|

“Keep on Keeping

on” with Exactrix Ultra Endurance 1890, 1895 and 1990 Single Disc

Seeders.

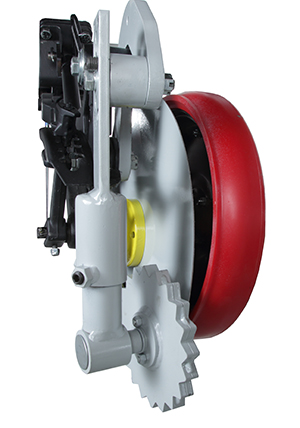

Ultra Endurance 1890,

1990, 1895. Banding deeper at 4.5 inch depths with exceptional wear

life.

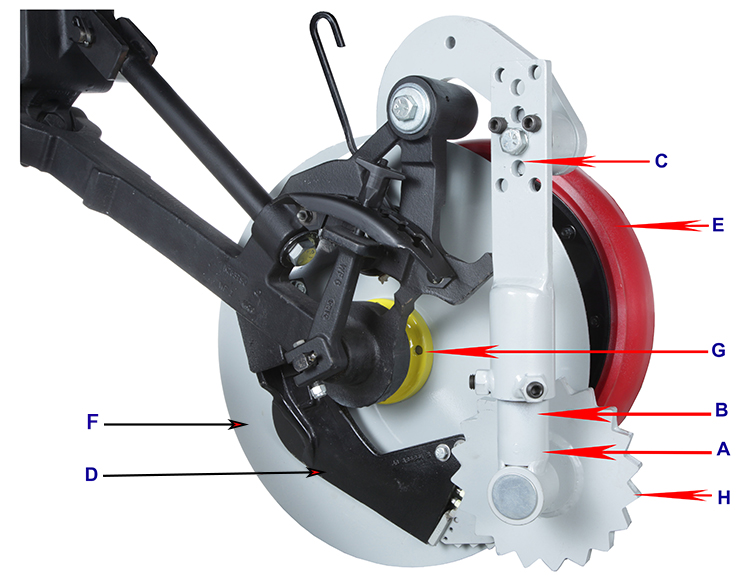

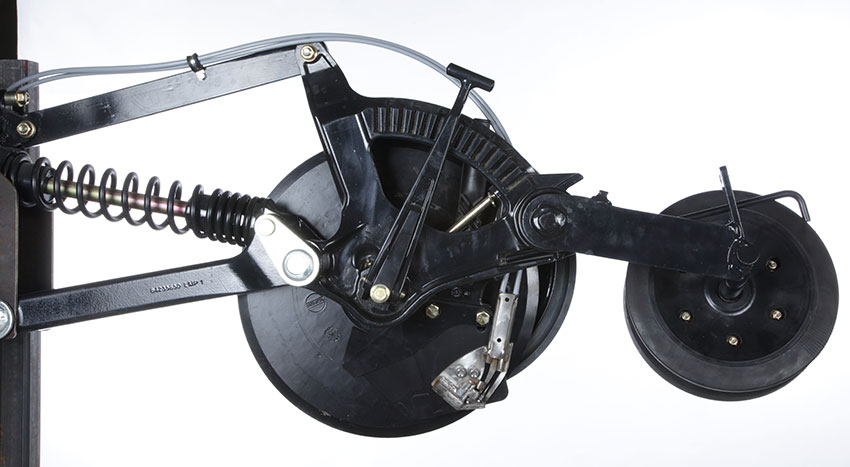

A.

Adjustable 20 point closing angle. Run the closing wheel straight or

angled. Get the right closure by changing the tow angle.

B.

Certain soil types require adjustable depth Exactrix closing wheels.

The closing wheel can be adjusted vertically with the telescope

shaft.

C.

Adjustable front to rear closing point in steep hill sides. Allows

the closing point to be moved immediately along side the Series 4.47

wing injectors. Closes seed rows from the side with immediate seal

closure of the slot. A powerful tool for the Wing Injection of

Exactrix NH3.

D. The

Exactrix banding boot runs in the shadow. Series 3.5 banding boot

with carbide steel slipper foot with double height adjustments (6

total).

E. Polyurethane depth wheel out lasts standard Deere rubber semi-pneumatic

tires by 5 times in soybean stubble.

F.

Yielder Manganese Steel Blades offer more wear life as compared to

standard Deere blades at 3/16 x 18 inch. The Yielder blades are

available in Manganese Steel, Single edged with exclusive extreme

edging of 3/8 x 19.6 diameter for banding only openers, and 5/16 x

19.1 diameter or seed openers.

G.

Steel Hubs allow the openers to penetrate to 4.5 inch depths.

Standard Deere bearings and seals are used. Bolts are 1/2 inch

stainless steel.

H.

Closing wheel diameters in 8, 10 and 12 inch. Also laminated in 8/10

and 10 x 12. All with 45 degree angle point loading for mud clean

out.

Most owners of Deere 1890/1895 single disc

drills have a great opportunity to bring more bushels to the elevator

every year.

Yielder drills

often outperform Deere 1890’s by 20 bushels per acre at Walla Walla,

Washington. That is a lot of money in today’s economics.

The first

Yielder drills are now over 31 years of

age and they still win the yield contest in winter wheat. So lots of

bushels are lost by the Deere 1890 due to poor seed placement or

seeding too fast for conditions. For certain

young farmers prefer Yielder Drills due to their excellent

reputation for full yield potential, seeding and application

uniformity.

Some of the

single disc drills released are limited to certain soil types, or may

have some type of seed delivery problem that the engineers knew

nothing about when the machine was released. Furthermore, many of the

single disc machine designs were based on Federal Crop Farming of

the last 25 years. Some single disc machines are not built for

highly persistent, and consistent yield, they are non-durable price

point machines that are purposely designed to meet a broad but

certain segment of the no-till single disc market.

Case SDX

Case SDX Review

HERE

The Case SDX is a good example of a

single disc seeder that needs help outside the machines area of

development. New seed boots and several updates are now available

for the SDX which expands the machines applicable market.

EXACTRIX SDX Winter Wheat

or

www.exactrix.com/KD.htm

provide information on the Case SDX.

Case 500 and Case 500T

Precision Disc Seeder. Fall 2013 release.

Get the

engineering review HERE

CASE 500T

CASE 500

The Case 500 T can also

be utilized and a single disc, No-tillage banding tool bar.

TAPPS and TAPPKTS can be banded deep.

Triplex Injection allows

up to three different nutrients to be delivered simultaneously.

Quickly change from

seeding mode to banding only mode.

High

Speed, No-tillage Deep Banding with Exactrix Triplex injection of

TAPPS and TAPPKTS.

Storage position when seeding.

Case Exactrix Wing

Injection or CEWI. Seeding and Wing Injection of APP/ATS/KTS and

deep banding of NH3, 10-34-0, 12-0-0-26S and 0-0-25K-17S.

For Mustard, Canola and

Flax producers can now shallow seed and allow liquid fertilizer

application outside the seed row for sensitive germination crops

such as Canola. Canola is sensitive to seed row N and S, and wing

injection is safe.

Soybeans on high soil pH.CEWI is ideal for Soygreen®.

Soybeans can be fertilized

with Iron Chelated Soygreen® to overcome Iron Chlorosis. A very

critical method is now available in VRT seeding and producers can

now raise soybeans on high pH soils. Wing Injection allows Soygreen®,

A Double Chelated Iron to be placed outside the germination zone, but

close to the seminal hair roots.

In heavy residue, seed placement allows NH3 to be applied, and

TAPPKTS can be applied for such crops as Milo, Sunflower, Triticale,

HRW Wheat, and SWW Wheat.

CEWI, Case Exactrix

Wing Injection.

Here are the options for

the Case 500 and 500T precision disc seeder.

1. High Speed, No-tillage,

Banding Deep in Triplex injection. Formulating TAPPS, TAPPKTS and

Fulvic acid at 5 inch depths.

Usually on the back gang

only with 7.5 inch drills producing deep bands on 15 inch centers.

32 openers on 60 feet.

10-inch banding centers

will produce the highest yields in pre-plant banding for small

grains. Canola seedings can be placed on top of the bands in an

index seeding approach. 72 openers on 60 feet.

Mounts inside the scraper.

$225.ea.

2. Case Exactrix Wing

Injection CEWI for deep bands and side banding when applying

10-34-0, 12-0-0-26S and and 0-0-25-17S. Banding deep at seeding

depths or seeding shallow with liquid fertilizer to the side of the

seed row, or side banded in a non-toxic location, applying TAPPS

and TAPPKTS in pre-plant and single pass.

Mounts along side the

scraper. $275. ea.

Drills set up 7.5 inch are

paired to share the back gang with 15 inch centers set up wing injection.

32 openers on 60 feet.

Drills set up 10 inch band

on 10 inch across the machine width. 36 openers on 60 feet.

3. For Deep Banding,

Yielder Manganese Steel blades at 5/16 x 22 and 3/8 x 23 in extreme

double edge and back edge. The larger diameter Yielder blades can

also be used for seeding with Case Exactrix Wing Injection.

Yielder Manganese Steel

blades work well in rock, as wear life is extended at least 5 times

over carbon blades.

5/16 x 22, $225.

3/8 x 23, $327.

The Deere 1890 is

a tillage, minimum till and No-till drill that has had good success

but is marginally applied in many No-till conditions. The 1890 is a

machine that needs improvements to make it better about 70% of the

time. In fact many problems exist with the machine that owners are

simply not aware of. One big factor is adequate weight.

Side Bar Click Here

For Additional Information On Owning And Operating Costs

After 14 years of

exposure to the 1860 and 1890 with Exactrix injection systems, Exactrix engineers have discovered several 1890 problems that can

be easily fixed. Many producers are not aware of these problems.

Why and how did

Exactrix engineers and owners discover these problems?

Producers with

Exactrix Wing Injection systems discovered the Deere 1890 problem.

When the openers do not properly engage the soil, a small amount or

about 1% to 5% of NH3 is lost. This immediate loss is reported

almost always to Exactrix. An investigation begins.

Exactrix

engineers now understand why some 1890’s work better than others.

Especially troublesome are the 7.5 inch 1890’s and the very light

weight, non-durable, 1690, which is no longer recommended. The

10 inch 1890 at 40 feet has been a good performer and yet it can be

improved.

The 30 foot 1895 is the best machine for seeding with

World Class Yields, high net margin from Exactrix TAPPS.

Side Bar - 2 Click

Here For Additional Information On

Seeding With The 90 Series Opener

The best seeder

from Deere is the 1895, raising top, world class yields. This machine

is often utilized in the rolling Palouse and

Southern Idaho irrigated wheat production. The 1895 has additional

frame weight per opener when set up at 30 feet. The machine

penetrates tough soils better than any other Deere single disc

machine. Seeding in tough conditions at 2.5 inches is common with

the Deere 1895.

Opener bounce,

poor upkeep, and opener operation in heavy residue

needs to be further explained to owners. Deere activists need to

train operators on how to seed properly with the 1890. The

limitations of the 1890 are seldom explained to the new owner.

Typically, Deere

1890’s on 10 inch can seed much faster than 7.5 inch drills.

Opener bounce is a problem with narrow spacing drills. A 42

foot 1890 on 7.5 inch spacing has 68 openers and they bounce to the

point the machine seed placement is not acceptable at almost any

ground speed. Some producers expand the 1890 to 72 openers making

the problem of opener bounce even worse.

1890 seeding

No-till…Reviewing the 10 inch 1890.

The 10 inch

version has 52 openers at 43 feet and the machine needs more weight.

A 10 inch 40 foot

1890 has 48 openers at 409 pounds per opener.

The 50 foot, 10

inch version has 583 pounds per

opener.

And 60 foot 10

inch has 555 pounds per opener.

The 60 foot 7.5

inch drill has 458 pounds per opener…

A 60 foot 1890 on

7.5 inch spacing must add 97 pounds per opener to seed like a 10

inch machine.

Therefore, 96

times 97 is 9,312 pounds of additional weight that must be added just to

seed like an 1890 on 10 inch.

Reference Deere Charts from their 2011

brochure at

www.JohnDeere.com

The producer

said, “Make it seed like a Yielder”.

Yielder drills

produce the highest dryland yields in North American agriculture

right to the top of the yield potential in winter wheat. The

machines are capable of producing 800 to 1,200 pounds per opener all

day long, plus the opener down pressure can be adjusted from the cab

to match the seeding speed. Two other major factors make the Yielder

Drill difficult to outcompete for yield, since the machine is not a

price point machine, it is a maximum yield machine.

Major Changes to

improve the 1890 opener performance.

1.

Remove the Free Link.

1D2161, Drop the tillage aspect of the drill. All the openers need

to engage with positive down pressure in rolling terrain, such

as terraces or steep slopes.

2.

Add

Frame weight evenly across the frame of the 1890 or 95. Add at

least 10,000 pounds. Use wheel weights in the center frame

corners. Use tractor weights at the back

to the center of the frame.

3. Change

the hydraulic cylinder size to 4 inch diameter.

Common SAE 4 inch cylinder, 8 inch stroke, $250., source locally.

Typically 6 to 9 cylinders

must be changed.

4. Remove

the Deere patented hydraulic pressure compensation valve

and install the X-16 Accumulator Ride Control. Allow the

opener pressure to be changed at the cab

by the operator. The X-16 ride control does not constantly consume

10 gallons per minute of hydraulic flow. The accumulators

are charged in ranges allowing each cylinder to respond

instantly. Electronic control of the opener ride is possible from

the tractor cab. 1D2191 Hydraulic Group.

1D2192 with electronic feed back and a plc performance loop.

Major

Changes to improve the 1890 endurance and opener performance.

Increase tractor seat time 4 to 5 times between maintenance events.

5. Change

the coulter blade diameter, thickness and hub strength.

Two choices are available.

Choice 1. Seeding and banding, wing injection 19.1 x 5/16 single

edged 1.25 inch. Yielder Manganese blades inclusive, steel hub design

with ½ inch hub

bolts. 1D2195.

Choice 2. Banding only, typically 19.6 x 3/8 single edged 1.5 inch

Yielder Manganese blades inclusive, steel hub design with ½ hub

bolts. 1D2196.

6.

Install carbided seed boots,

tripling the wear life of the standard boot. 1D2212,

7.

Install Martin 20 point closing wheels,

point loads the closing and

removes opener load.

8. Install

Martin 2,3/4 in. heavy duty depth wheels; reduces opener bounce,

leaves more standing stubble, and appears to be more durable when

sourced from Martin.

Changes that

improve seeding.

9. Install

Needham seed tabs.

10. Install

the Needham narrow firming wheel.

11.

Install Ag Pro seed metering system for best seed delivery and

uniformity. A lower box can be added to the Deere 1990; best metering

system for high value seed that is GMO.

Any 1890 can be made into a 1990 when the Ag Pro seed box is added.

Great tool for Garbanzo Beans, the Ag Pro Meter.

12.

Air

Brakes from Needham relieve air pressure for improved seed delivery.

13.

Install the latest 1910 Deere towers with orifice coefficient

design.

14.

Consider Needham seed splitters for Deere Towers.

15.

Set

up the down pressure circuit to produce 600 pounds per opener and

“go to school” and seed deeper. Seed at least 2.5 inches in heavy

residue conditions. The Deere 1890 opener allows deeper

seeding in heavy residue with the unique narrow seed firming wheel

and the 20 point Martin closing wheel

design. Infrared light can penetrate much deeper when the seed is

not packed from the soil surface. The Deere 1890 works

very well when the seed is delivered into the “Buffered

Zone” at the 2.25 inch to 2.5 inch depth. Do not add row

cleaners. Producers have best results

with deeper seedings in heavy residue. The opener can do it. A

review of the combine spreading should be carried out each harvest

season.

Taking Yield to

the Limit.

16.

Install Exactrix Wing Injection and apply TAPPS.

Apply TAPPS with Humic Acid, or apply TAPPKTS with Humic acid and

micros. $275 per opener.

17.

Install banding-only Series 4 scrapers with Exactrix TAPPS

formulator tubes.

Two-pass the nutrient application. Band

in the fall for spring crops. Band into growing wheat or sod in the

late fall and early

spring. $150 per opener.

In

steep slopes, Series 3.5 is recommended. Series 4 is not recommended

for high yielding winter wheat and high yielding spring crop areas.

18.

Making the above changes will change the recommended seed

rate. Most likely the seed rate is now too high if the above adjustments

have been made. Since the germination and

emergence are more, uniform the seed rate will need to be adjusted with a

series of test plots. Once uniformity is

employed with near perfect seed depth, seeding at the proper seed

rate could easily pay for the entire drill and the all the above

changes.

19.

Exactrix will pay $1,000 for any test plot submitted under STEEP

criteria.

Operating the machine with the above improvements could improve the

operation so much that both nutrients and seed rates need to

be adjusted. Old techniques and rates may no longer apply. Some

producers could easily be beyond the

economic point of diminishing returns and on the back side of yield

curve.

Typically

producers consider the Deere 1890 as a seeder. The 1890 is also a

good Pre-Plant Bander for corn production. The machines are set

up on 10,12, and 15 inch band spacing, or Exactrix wing injection is

used on 10 and 15 inch spacing. Also the 1890 can side dress

winter wheat at the lowest cost per acre. Lower owning cost is

realized since the same machine is covering up to 3 times more

acres. Large acre operators may have a dedicated single disc banding

tool bar. Smaller operators can use their 1890 to cover more acres in

a dual purpose utilization.

Lowering Banding

Costs, Increasing Ground speeds to 9 mph.

Banding into

heavy residue is much more effective when the 1890 can run 4 to 5

times longer between repairs, maybe as high as 60,000 acres with a

60 foot machine before repairs, thus lowering banding and fuel costs

to the lowest common denominator. Use the accumulator ride control

to set down-pressure from the cab.

No-tillage Deep

Banding….and

in all cases with the Ultra Endurance 1890, the new machine

design will go to 5 inch depth with virtually no soil disturbance in

very difficult soil conditions.

Review of the

1890 seeding at 7.5 inch and 6 inch, and the Fisher 1890, 42.5 foot

machine.

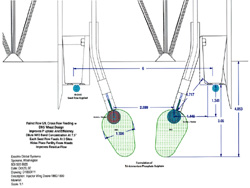

In 2011 at

Fisher, Minnesota, a 15 inch band spacing was implemented with the

7.5 inch 1890 drill

utilizing Exactrix Wing Injection on 34 rear gang openers. The front

gang was paired to the dedicated wing injection opener of the back

gang.

The 1890, 7.5

inch average rows were paired to 4/11 allowing sunlight to penetrate

into the canopy, resulting in off row light effect. The effectiveness of the machine was greatly improved. Both

seed rows received uniform nutrient without starving the non-wing

injected row. This arrangement was also utilized on Yielder Drills

using the NP opener in combination with the Swanson offset, leading

double disc opener or SOLDD. The single disc NP opener seeded and

banded and offset, leading double disc or SOLDD only seeded. This

Dual Opener arrangement (NP plus SOLDD) was considered by many

producers as the best possible compromise for all seeding

conditions.

The same Deere

1890 with Exactrix wing injection of 15 inch centers was utilized

for Pre-plant banding of TAPPS for sugar beets and corn, by raising

the front gang and banding to the maximum depth with the rear gang

only. Raising the front gang also added additional machine weight.

This particular

arrangement was further improved in the fall of 2011 by adding

Exactrix steel hubs and coulters to the back gang. The John Deere

Free Link was removed by adding spacers.

The Red River

Valley, Fisher 1890

was further improved by changing the hydraulic cylinders to 4 inch

diameter SAE, with the standard 8 inch stroke. The 2.5 inch and 3

inch cylinders were deleted since they cannot produce enough down

pressure at maximum operating pressure on the outside opener wings.

The 7.5 inch

drill can be adapted to Exactrix TAPPS by setting the machine up as

a single pass machine applying and seeding as paired row 4/11.

The 7.5 inch

machine can also be set up as single pass, and band on 15 inch row

spacing for winter wheat and crops, such as Winter Canola.

The 15 inch

banding arrangement with 19.1 inch coulters, steel hubs and larger

hydraulic cylinders, can be set up to side dress the established

winter crops in late fall or early spring.

The advantage of

15 inch band spacing with 7.5 inch row spacing is also observed in

establishment and fertilization of alfalfa, and high yielding winter

canola under center pivots.

Reviewing the

1895 at 30 feet, The Genesee 1895.

A Deere 1895

equipped with Exactrix TAPPS at Genesee, Idaho

has proven to be an admirable, high yielding machine because of

adequate machine weight when seeding and banding. In the spring of

2011, the 1895 was converted to Exactrix 19.1 inch x 5/16 inch

coulters with steel hubs. The experiment was carried out to improve

band depth, to improve endurance, and hopefully take a bit higher

yield as a result of the 5 inch banding capability.

Some of the field-wide averages with the 1895 exceeded 125 bushels per acre at the

dryland winter wheat harvest in 2011.

The Genesee 1895

weighs 185% more than a standard 1895. A standard 1890 weighs in

from the factory at 24,000 pounds. The Genesee 1895 weighs 42,000

pounds loaded, 18,000 more pounds than the standard 1895. With the

NH3 tank empty, the Ag-Pro equipped machine weighs 32,500 pounds.

The Genesee 1895

loaded can produce 777 pounds per opener with positive down pressure

on the wings. The seeder has 54 total openers with 36 seeding and 18

banding. The Deere banding openers MRB have been modified with

Exactrix steel hubs and Yielder manganese steel blades, allowing the

machine to produce superior economics in the range of 125 to 150

bushels per acre of winter wheat.

The reason for

the coulter blade change was the Deere factory 3/16 carbon blades

were not durable. The factory 3/16 carbon blades would bend and

deflect the cast iron hubs when operating on steep Palouse Hills.

The 3/8 carriage bolts would snap or the cast iron hub would break

when operating the Deere 1895 on 50% compound angle slopes. These

are tough conditions, requiring a belted 75 tractor such as a

Caterpillar Challenger for the 30 foot machine. The change to the

articulated 450 hp Case Quad track did not improve the MRB cast hub

breakage problem.

The discovery by

producer Eric Odberg was the larger 19.1 inch Exactrix Yielder

manganese steel blade produced superior performance on slopes,

plus the additional depth of penetration of the opener. In fact, the

band depth was observed at 5 inches as measured in soil slot in the

field conditions of spring 2011.

In the fall of

2011, the full force of the machine was utilized at 777 pounds per

opener to deep band and seed the winter wheat crop. The

conditions were difficult for sure with much improved performance for the operator.

The Exactrix hub

and coulter blade change was a major achievement. The Genesee 1895

did have improved slope stability. The Exactrix steel hub in

combination with the 5/16 Yielder coulter blade would hold the

machine on the hillside without damage to the soil or a slide out of

the machine.

Shank Vs Single Disc |